At our company, we combine traditional craftsmanship with advanced technologies to ensure precise production and high-quality metal processing. We use a wide range of machinery and proven methods for both custom and serial manufacturing.

Sheet Cutting – 3D Laser and CNC Plasma

Ideal for architectural applications, design, exhibitions, and advertising

Custom patterns, design sheets, and serial production

We create detailed patterns, decorative cut-outs, and perforations based on customer requirements.

Creative technology for both functional and aesthetic metal designs.

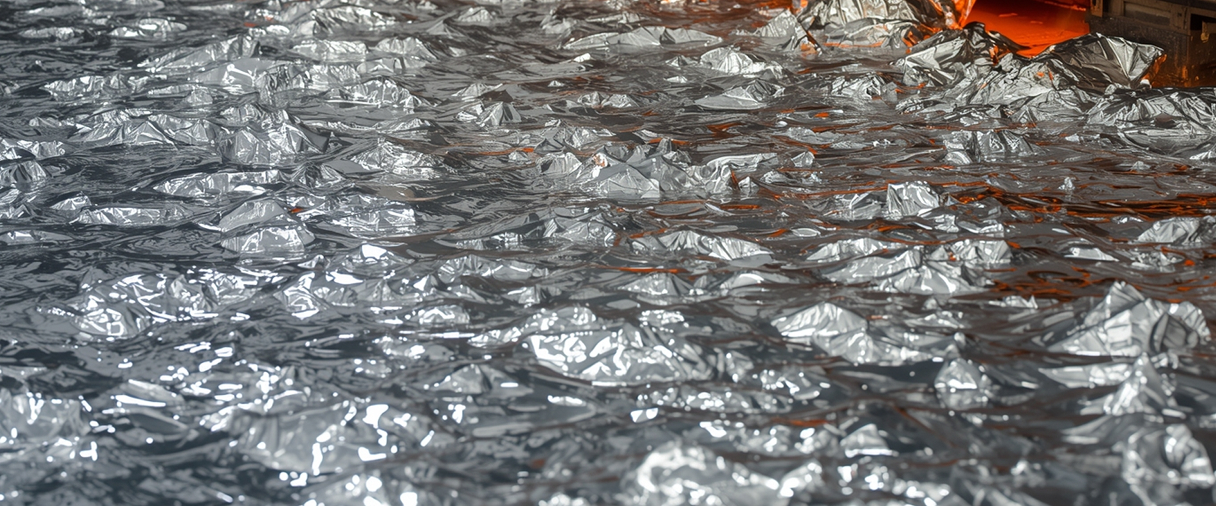

Surface Finishing

Powder coating – efficient surface finishing with cutting-edge technology

Electrostatic synthetic painting using GRACO equipment

We provide professional surface finishing to protect metal products against corrosion and improve their visual appearance.

We coat metal parts up to 6.4 metres in length. All products are thoroughly cleaned and degreased before coating.